- Overview

- Product Description

- Consumable list

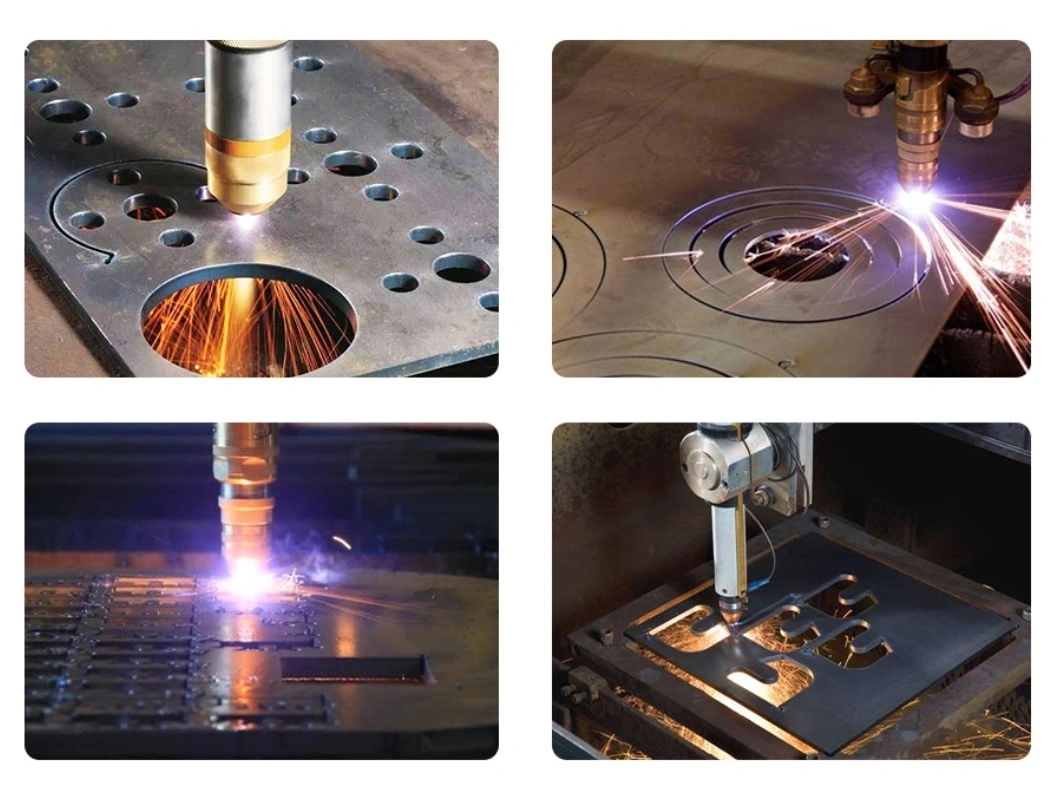

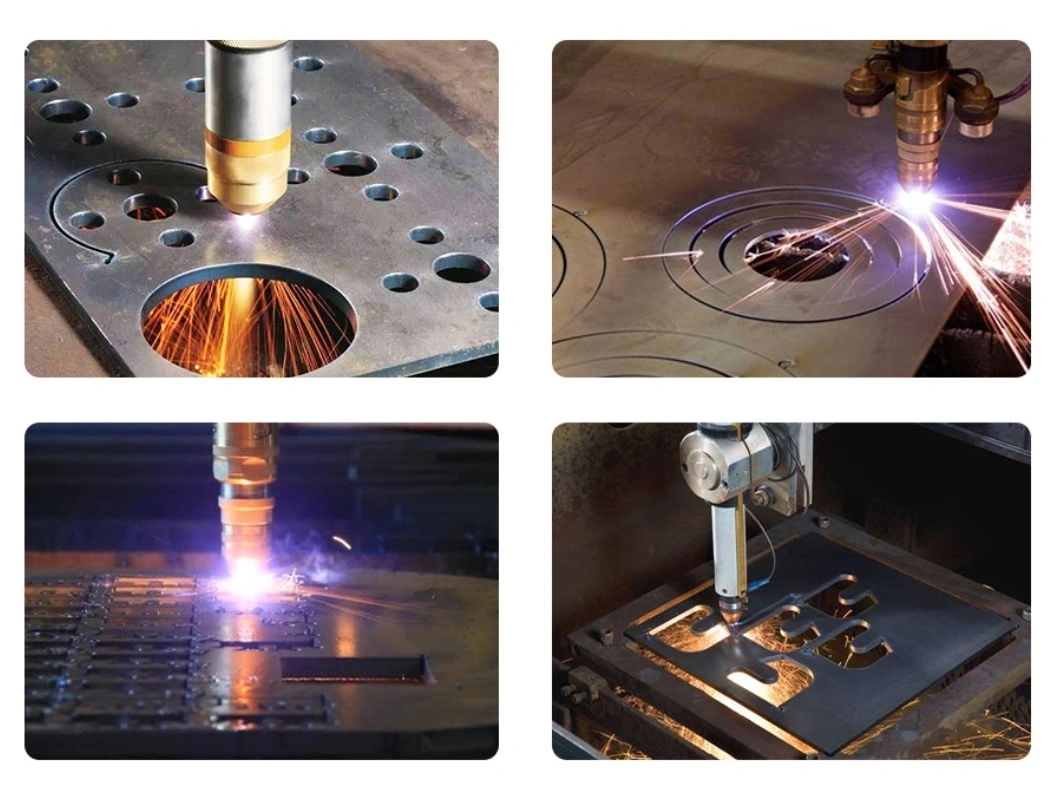

- Application

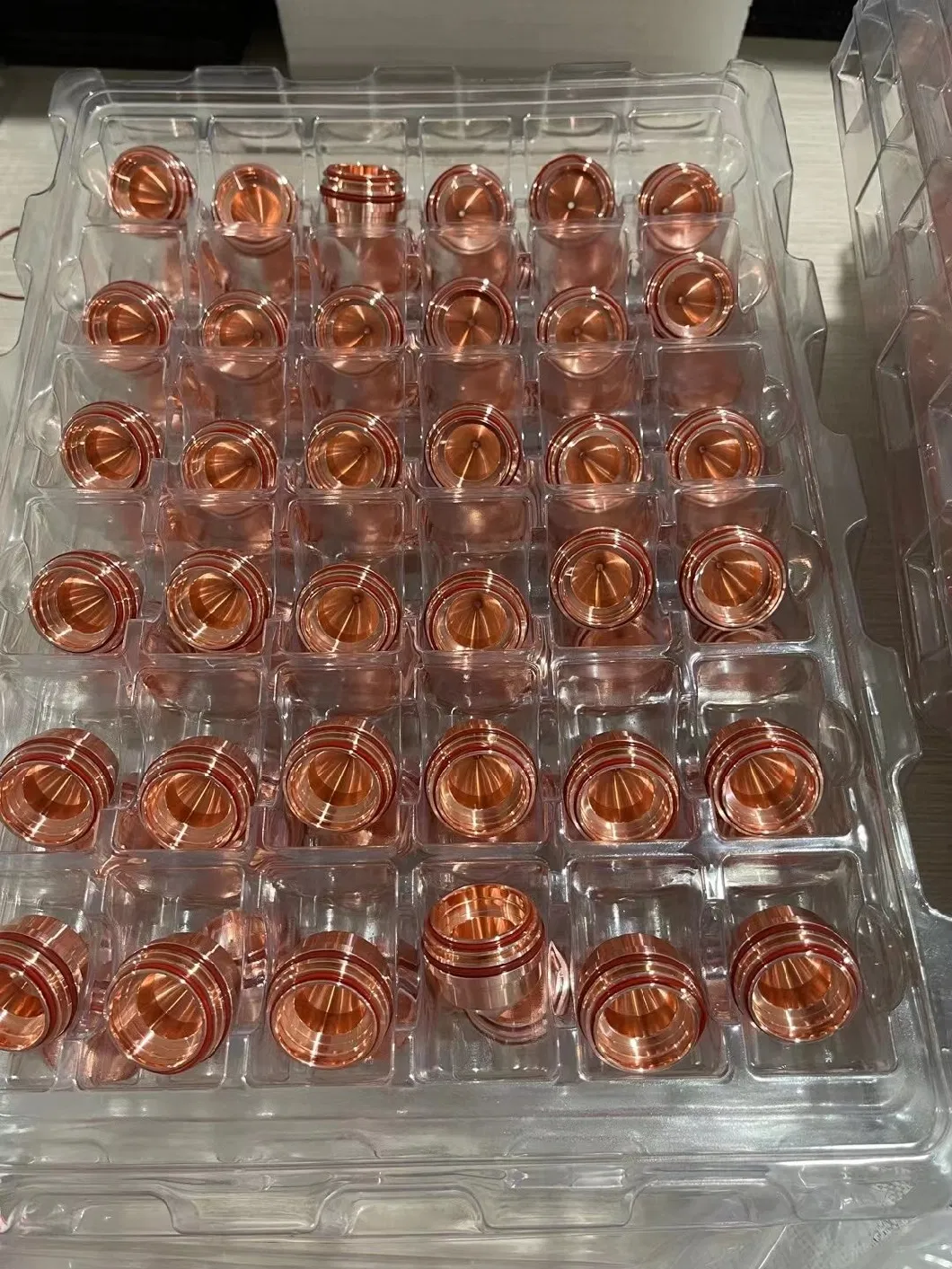

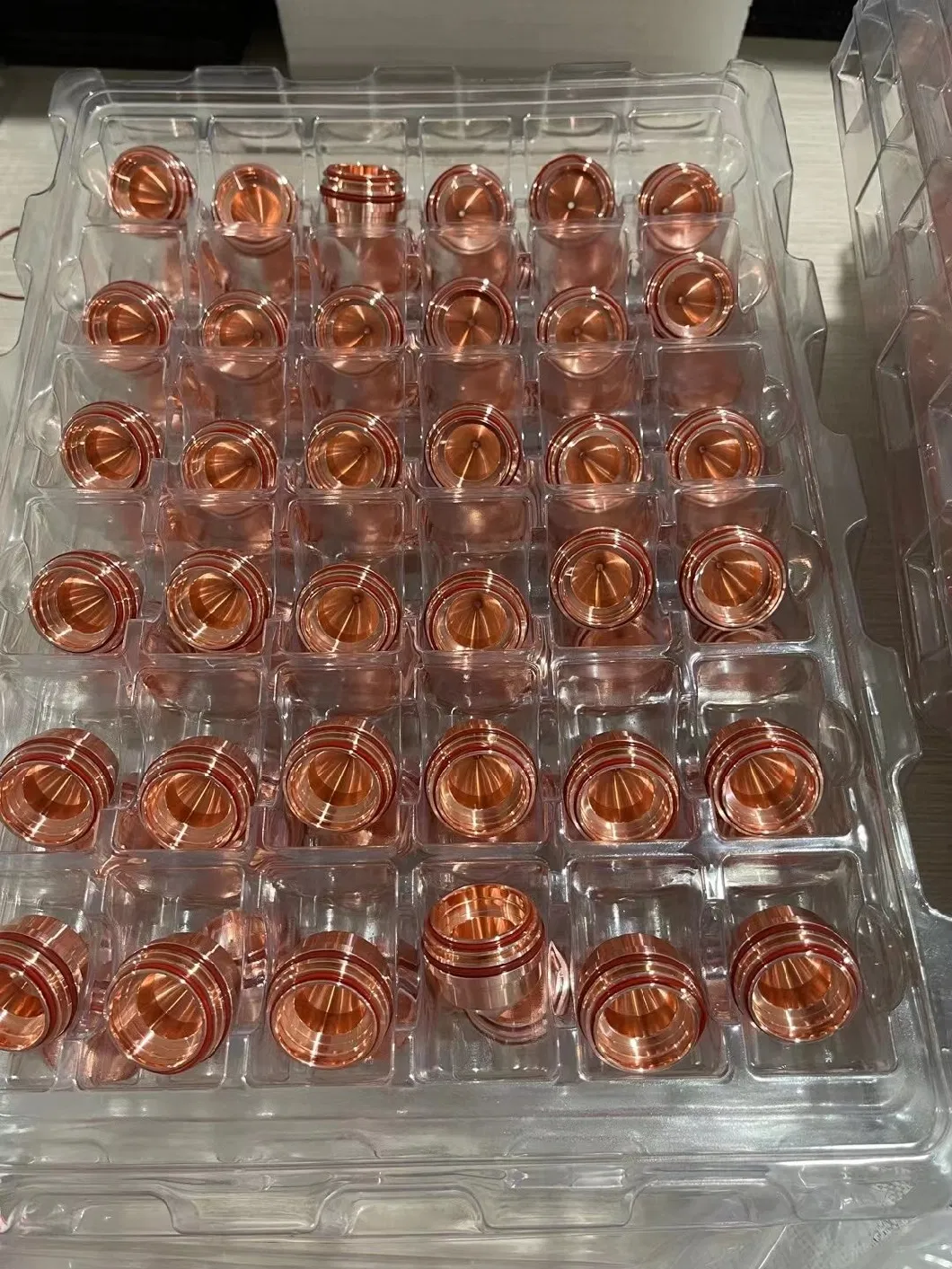

- Packaging & Shipping

- Company Profile

- Certifications

- FAQ

Basic Info.

Model NO.

Swirl Ring 220857

Certification

CE, RoHS, GS, ISO9001

Standard

DIN, ASTM, GOST, GB, JIS, ANSI, BS

Customized

Customized

Material

Metal

Application

Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Nozzles Holes

Powermax85A

Cutting Torch

Protect Cap

Torch Model

Powermax85A Torch

Plasma Accessories

Torch Nozzles & Electrode

Electrode

Plasma Cutter

Ampere

50A/80A/130A/200A/260A

Plasma Torch Style

Powermax65A Torch

Plasma Torch Consumables

Electrode 22084

Consumables for Cutting Machine

Electrode Nozzle

Cutting Tools

Plasma Nozzles Electrode

Spare Part Kits

Plasma Cutter Tips

Powermax Shield

Plasma Cutter Tips

Packaging Unit

5 Stuck Unit

Modle Number

220819 220817

Plasma Consumables Shield

220854 220842

Transport Package

Carton Box

Specification

brass/copper

Trademark

OEM

Origin

China

HS Code

8468900000

Packaging & Delivery

Package Size

6.70cm * 1.70cm * 1.70cm

Package Gross Weight

0.025kg

Product Description

Long Service Life Plasma Cutting Nozzle 220816 Swirl Ring 220857 with Factory Price

What are plasma cutter consumables ?

Plasma cutter consumables are a set of components in your plasma cutter that gradually wear over time until they need to be replaced: they have a life cycle. The consumables are all found in the cutting torch itself, which is where most of the energy is focussed, and keeping track of wear and tear is a key part of maintaining an efficient machine that cuts well and lasts a long time. Plasma cutting torch consumables include: a swirl ring, electrode, nozzle, retaining cap, and shield cap.

Nozzle:

The nozzle focuses the plasma arc and the gas that surrounds it to make a clean and precise cut. A nozzle with a larger opening is used for gouging, while a nozzle with a smaller opening is better able to direct the gas and so is used for fine, detailed work

Electrode:

The electrode is a narrow piece of copper containing hafnium (which is an excellent conductor of electricity). Its job is to receive the electrical current from a cathode block inside the torch to which it is connected, and to focus the charge through its tip, which causes it to arc onto the workpiece.

Retaining cap:

The retaining cap essentially holds all of the consumable parts of the torch together. As temperatures at this end of the machine are extremely high, it's not just the parts creating and focussing the arc that are worn down; the component holding them together also degrades over time.

The retaining cap essentially holds all of the consumable parts of the torch together. As temperatures at this end of the machine are extremely high, it's not just the parts creating and focussing the arc that are worn down; the component holding them together also degrades over time.

Shield cap:

The shield is there to protect the torch and its other components from the sparks and molten metal that result from the plasmacutting process. It takes the brunt of the fallout so that wear to other components is minimised as much as possible.

cutting process.

Question2 : How can we install the consumables?

Answer : Friendly English version manual and operation video CD disk.

Question 3: How do I choose the right consumables for my machine?

Answer : According to your needs and budget, we will provide the best answer for your efficient production.

Question 4: When can I get the price?

Answer : We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

Question5: Can I have a visit to your factory before the order?

Answer : Yes, look forward to communicating and cooperating with you.

The shield is there to protect the torch and its other components from the sparks and molten metal that result from the plasmacutting process. It takes the brunt of the fallout so that wear to other components is minimised as much as possible.

cutting process.

| Consumable Type | Torch Type | Amperage | Shield | Retaining cap | Nozzle | Electrode | Swirl ring |

| Drag-cutting | Hand | 45 65 | 220818 | 220854 | 220941 220819 | 220842 | 220842 |

| Mechanized | Machine | 45 65 | 220817 220955 | 220854 220953 | 220941 220819 | 220842 | 220857 |

| FineCut | Hand Machine | 45 | 220931 220948 | 220854 220953 | 220930 | 220842 | 220947 |

| FlushCut | Hand/Machine | 30-45 | 420540 | 420536 | 420536 | 420635 | 420634 |

| Max control gouging | Hand/Machine | 20-65 | 420480 | 220854 | 220797 | 220842 | 220857 |

| Max removal gouging | Hand/Machine | 20-65 | 220798 | 220854 | 220797 | 220842 | 220857 |

| Item | Value |

| Customized support | OEM |

| Place of Origin | China |

| Product name | Powermax85 |

| Material | Tellurium copper |

| OEM | Accept OEM |

| Package | 5 pcs/ box |

| Delivery time | 5-7Days |

Established in 2017, ALLWINCNC are a manufacturing company specializing in the production of plasma and laser consumables.

We want to build long-term relationships with customers rather than developing one-off deals.

By providing our products to help you succeed in your endeavors.

The core idea of ALLWIN is our commitment to achieving mutual success for our customers, shareholders, and employees through collaboration.

Question1 : How about your after service ?

Answer : Technical support by phone, e-mail or MSN around the clock.Question2 : How can we install the consumables?

Answer : Friendly English version manual and operation video CD disk.

Question 3: How do I choose the right consumables for my machine?

Answer : According to your needs and budget, we will provide the best answer for your efficient production.

Question 4: When can I get the price?

Answer : We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

Question5: Can I have a visit to your factory before the order?

Answer : Yes, look forward to communicating and cooperating with you.