Basic Info.

Model NO.

PHQ-1.6

Loading Method

Dynamic Load

Display

Digital

Control

Computer Control

Weight

100-500Kg

Power Source

AC220V

Oil Cylinder Position

Under

Length

900 Mm

Width

700 Mm

Height

1150 Mm

Gross Weight

240 Kg

Transport Package

Packed in Fumigated Wood Box

Specification

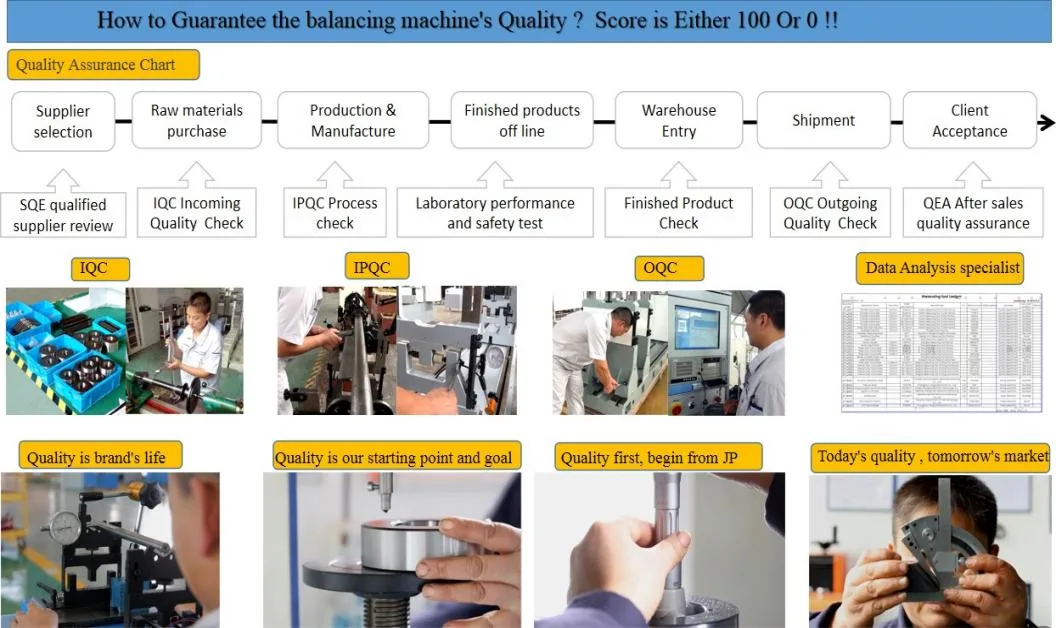

ISO9001: 2008 CE SGS

Trademark

JP

Origin

Shanghai China

HS Code

90311000

Production Capacity

1000 Set/Sets Per Month Negotiation

Product Description

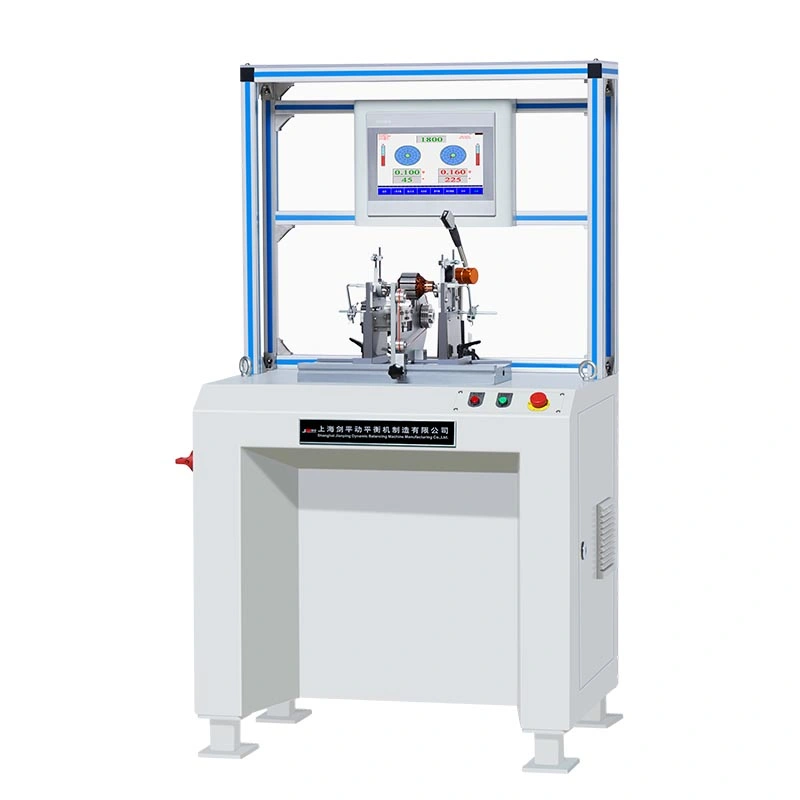

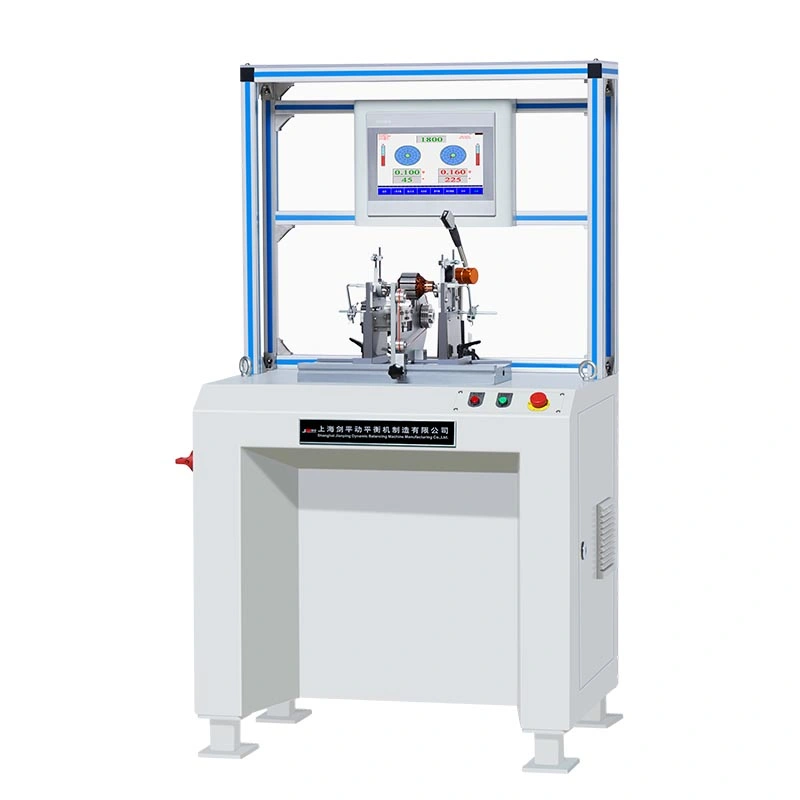

Pendulum frame textile machinery balancing machines (PHQ-1.6)

Production Description

Specially designed brackets transmit mechanical force with low vibration damping

Durable and reliable sensor possesses good linearity

Permanent calibration brings high accuracy with a permission of large initial unbalance amount

Belt-driving offers higher precision and easier operation

Advanced electrical measuring system and friendly man-machine interface

Modular design offers a wide range of application

Production Parameters

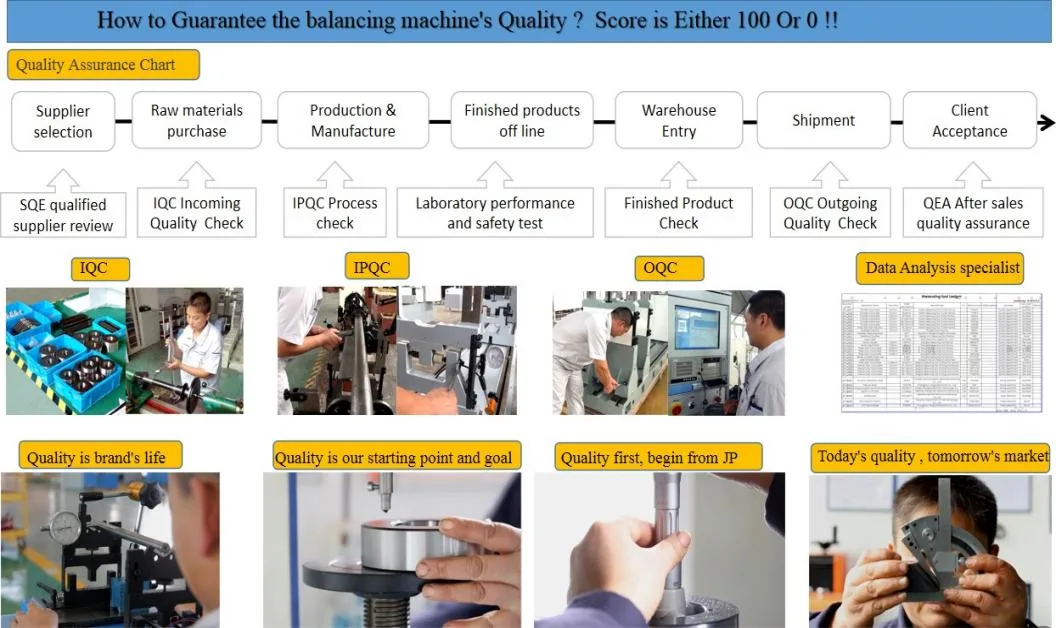

Delivery inspection

Range of Application

Balancing Machine for Car Rotor (PHQ-1.6) is also widely used in balancing rotatable bodies, such as kinds of micro-sized motors rotors, impeller, fans, crankshaft, turbocharger, water pump, roller, grinding wheel, main shaft of machine tool, textile machinery, tool, spindle, etc...Driven by belt, equipped with Variable speed motor to drive. Which ensures high quality balancing and precision. Quick booting, easy operation. And high efficiency

Factory Outlook

Special Features

The measuring unit employs JP-380 Micro- computer Electric Measuring Instrumentation newly developed by ourselves with piezoelectric transducer as electromechanical sensor. The measuring unit can show rotating speed, measured value, and phase position intuitively with options of six support modes available while the piezoelectrical sensor possesses a large capacity of output, small volume and high stability.

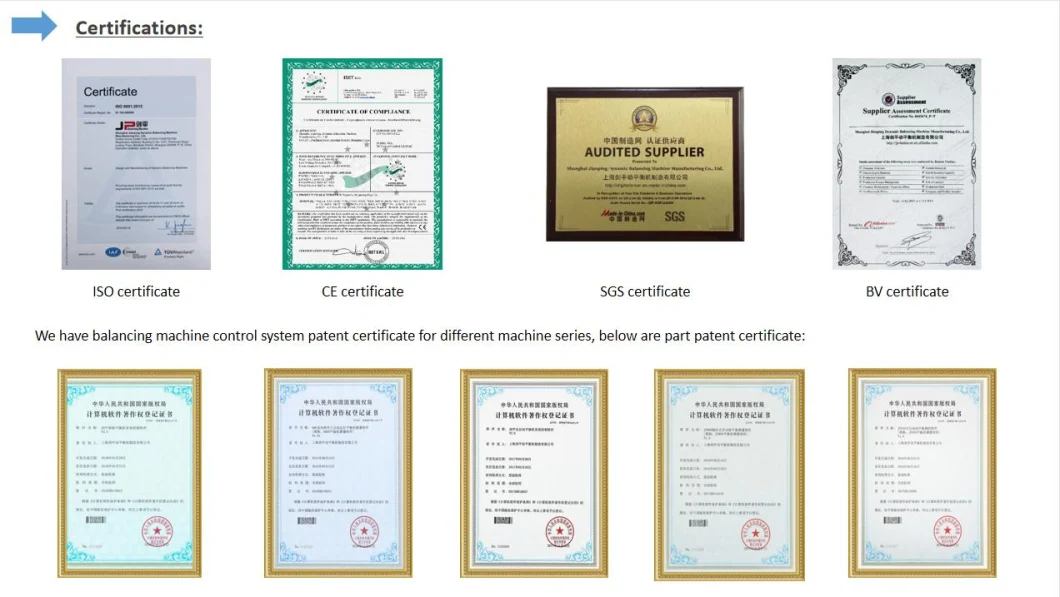

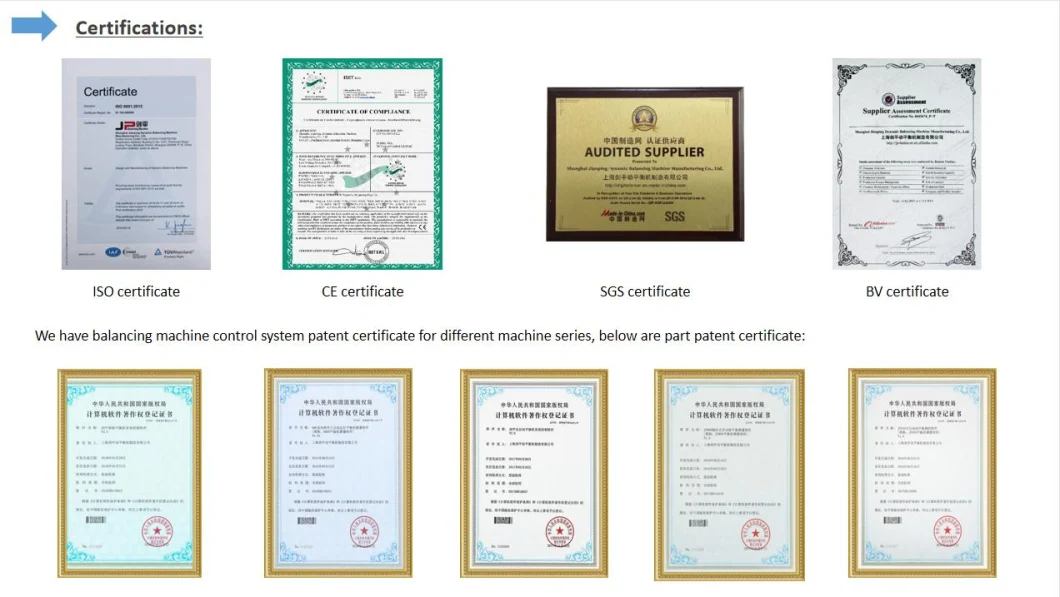

Certificates

Production Description

Specially designed brackets transmit mechanical force with low vibration damping

Durable and reliable sensor possesses good linearity

Permanent calibration brings high accuracy with a permission of large initial unbalance amount

Belt-driving offers higher precision and easier operation

Advanced electrical measuring system and friendly man-machine interface

Modular design offers a wide range of application

Production Parameters

| Technical data at a glance | PHQ-1.6/5 |

| Max Mass of Workpiece (kg) | 1.6/5 |

| Max Diameter of Workpiece (mm) | 260 |

| Distance between Two Support Bearings (mm) | 15-400 |

| Journal Diameter Scope of Workpiece (mm) | 3~40 |

| Diameter Scope of Driving Belt (mm) | 20~85 |

| Rotation Speed when the Diameter of Driving Belt is 100mm (r/min) | 185,335,390,700 Stepless speed regulation |

| Motor Power (kw) | 0.15DC Stepless speed regulation |

| Min Achievable Residual Unbalance Amount (emar) | ≤ 0.3g. mm/kg |

Range of Application

Balancing Machine for Car Rotor (PHQ-1.6) is also widely used in balancing rotatable bodies, such as kinds of micro-sized motors rotors, impeller, fans, crankshaft, turbocharger, water pump, roller, grinding wheel, main shaft of machine tool, textile machinery, tool, spindle, etc...Driven by belt, equipped with Variable speed motor to drive. Which ensures high quality balancing and precision. Quick booting, easy operation. And high efficiency

Factory Outlook

Special Features

The measuring unit employs JP-380 Micro- computer Electric Measuring Instrumentation newly developed by ourselves with piezoelectric transducer as electromechanical sensor. The measuring unit can show rotating speed, measured value, and phase position intuitively with options of six support modes available while the piezoelectrical sensor possesses a large capacity of output, small volume and high stability.

Certificates