Basic Info.

Power

Ultrasonic

Control System

Touch Screen Intelligent

Welding Route

up to 100mm

Usage

Plastic Welding

After-Sale

Oversea Service

Frequency

15kHz / 20 kHz / 35kHz ./ 40kHz

Weight

100kg

Welding Metgod

Ultrasonic Welding

Transport Package

Export Wooden Packing

Specification

800x 950x 1900mm

Trademark

BONNE

Origin

Wuxi, China

HS Code

8515809090

Production Capacity

10000 / Year

Product Description

Ultrasonic Plastic Welding Equipment

Principle of ultrasonic plastic welding

When the ultrasonic wave acts on the thermoplastic plastic contact surface, it will produce tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper weldment. Because the welding area is two The acoustic resistance is large at the welding interface, so local high temperature will be generated. In addition, due to the poor thermal conductivity of the plastic, it cannot be distributed in time for a while, and it gathers in the welding area, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, it merges into one. When the ultrasonic stops, let the pressure continue for a few seconds to make it solidify and shape, thus forming a strong molecular chain, achieving the purpose of welding, and the welding strength can be close to the strength of the raw material. The quality of ultrasonic plastic welding depends on three factors: the amplitude of the transducer's welding head, the applied pressure and the welding time. The welding time and welding head pressure can be adjusted, and the amplitude is determined by the transducer and the horn. There is an appropriate value for the interaction of these three quantities. When the energy exceeds the appropriate value, the melting amount of the plastic is large and the welded material is easily deformed; if the energy is small, it is not easy to weld firmly and the applied pressure cannot be too large. The optimal pressure is the product of the side length of the welded part and the optimal pressure per 1mm of the edge.

Welding advantages

Advantages of ultrasonic plastic welding: fast welding speed, high welding strength and good sealing;

Replace the traditional welding/bonding process, low cost, clean and pollution-free, and will not damage the workpiece;

The welding process is stable, and all welding parameters can be tracked and monitored through the software system. Once a fault is found, it is easy to eliminate and maintain.

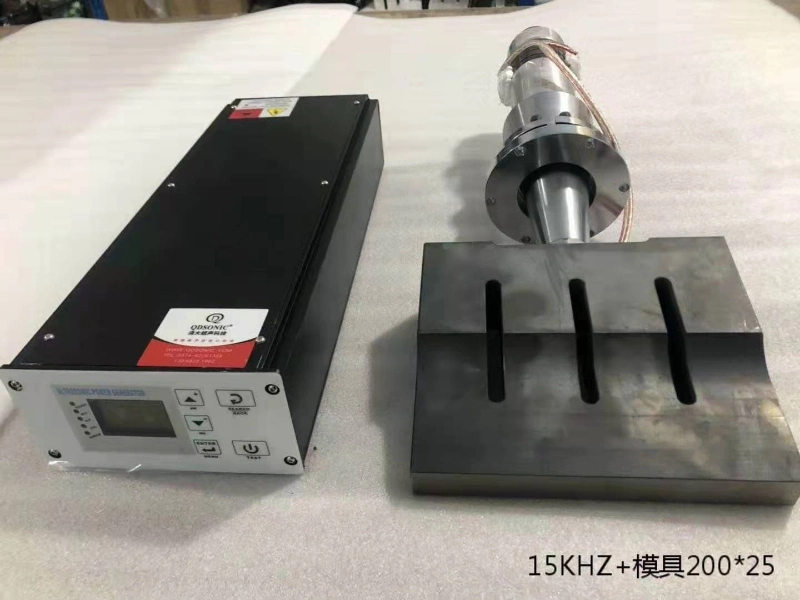

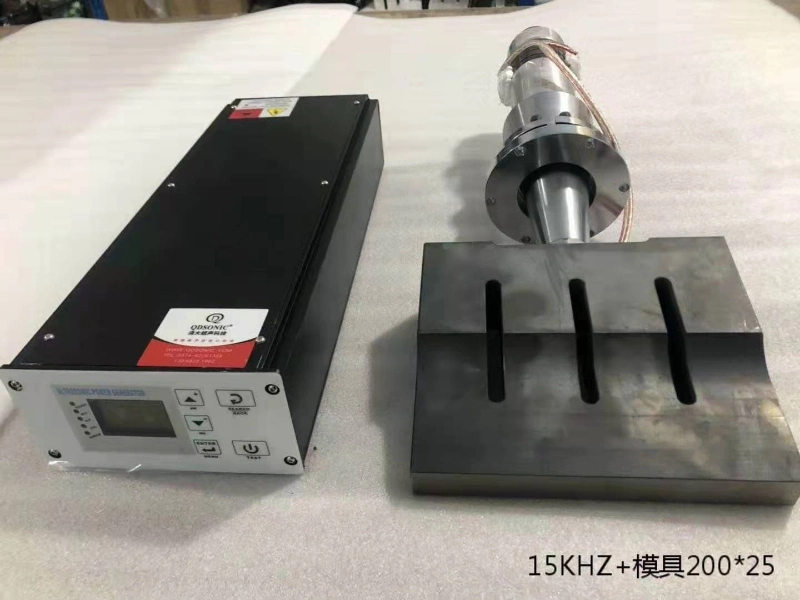

components for ultrasonic welding machine

Ultrasonic welding

Thermoplastics are a welding method in which two plastics are welded together due to the friction and heat generated by the surface molecules under the action of ultrasonic vibration.

Note for welding of thermoplastics:

A. The tongue and tongue design ensures convenient alignment during the welding cycle.

B. The welding wire is designed to be slender, but there must be enough meltable material to fuse the welding surface. The specific design method depends on what kind of workpiece equipment is used for welding. Welding pressure, vibration amplitude and other parameters are adjustable to ensure that the welding head can contact the welding surface and apply pressure. The lower workpiece is the pressure-receiving part and is placed in the bottom mold without moving. The welding head produces high-frequency ultrasonic waves, which makes the upper workpiece heat and vibrate, so that it can fuse with the lower workpiece. After the welding head stops vibrating, the pressure is maintained to cool the melting position. The entire welding time is mostly less than one second.

Ultrasonic welding machine with touch screen

Packing for shipment

Packing for shipment

Why choose bonne?

We firmly believe that we have excellent ultrasonic welding solutions for every application.

In addition to accuracy, strength and minimum particle release, process verification and traceability are also important quality standards. Ultrasonic welding is considered the most suitable joining technique.

From the initial idea to actual application and development, to process optimization, bonne will go hand in hand with you to provide you with the best solution.

Principle of ultrasonic plastic welding

When the ultrasonic wave acts on the thermoplastic plastic contact surface, it will produce tens of thousands of high-frequency vibrations per second. This kind of high-frequency vibration with a certain amplitude will transmit the ultrasonic energy to the welding area through the upper weldment. Because the welding area is two The acoustic resistance is large at the welding interface, so local high temperature will be generated. In addition, due to the poor thermal conductivity of the plastic, it cannot be distributed in time for a while, and it gathers in the welding area, causing the contact surface of the two plastics to melt rapidly, and after a certain pressure is applied, it merges into one. When the ultrasonic stops, let the pressure continue for a few seconds to make it solidify and shape, thus forming a strong molecular chain, achieving the purpose of welding, and the welding strength can be close to the strength of the raw material. The quality of ultrasonic plastic welding depends on three factors: the amplitude of the transducer's welding head, the applied pressure and the welding time. The welding time and welding head pressure can be adjusted, and the amplitude is determined by the transducer and the horn. There is an appropriate value for the interaction of these three quantities. When the energy exceeds the appropriate value, the melting amount of the plastic is large and the welded material is easily deformed; if the energy is small, it is not easy to weld firmly and the applied pressure cannot be too large. The optimal pressure is the product of the side length of the welded part and the optimal pressure per 1mm of the edge.

Welding advantages

Advantages of ultrasonic plastic welding: fast welding speed, high welding strength and good sealing;

Replace the traditional welding/bonding process, low cost, clean and pollution-free, and will not damage the workpiece;

The welding process is stable, and all welding parameters can be tracked and monitored through the software system. Once a fault is found, it is easy to eliminate and maintain.

components for ultrasonic welding machine

Ultrasonic welding

Thermoplastics are a welding method in which two plastics are welded together due to the friction and heat generated by the surface molecules under the action of ultrasonic vibration.

Note for welding of thermoplastics:

A. The tongue and tongue design ensures convenient alignment during the welding cycle.

B. The welding wire is designed to be slender, but there must be enough meltable material to fuse the welding surface. The specific design method depends on what kind of workpiece equipment is used for welding. Welding pressure, vibration amplitude and other parameters are adjustable to ensure that the welding head can contact the welding surface and apply pressure. The lower workpiece is the pressure-receiving part and is placed in the bottom mold without moving. The welding head produces high-frequency ultrasonic waves, which makes the upper workpiece heat and vibrate, so that it can fuse with the lower workpiece. After the welding head stops vibrating, the pressure is maintained to cool the melting position. The entire welding time is mostly less than one second.

| Model | FU 2025 P | PTS-2000 | DS 300 | DS 400 |

| Frequency | 15-35 KHZ | 15-40 KHZ | 15-20 KHZ | 15-40 KHZ |

| Power | 1200-3200W | 800-4200W | 4200-6000W | 800-4200W |

| Pressure | 0.1-1.0 MPA | 0.1-1.0 MPA | 0.1-1.0 MPA | 0.1-1.0 MPA |

| Voltage input | AC220-240V | AC220-240V | AC220-240V | AC220-240V |

| Welding route | 100 mm | 75-100 mm | 100 mm | 75-100 mm |

| Output time | 0.01-9.99 S | 0.01-9.99 S | 0.01-9.99 S | 0.01-9.99 S |

| Working mode | Time/ground/energy/depth/ pressure mode | Time / ground / ressure mode | Time / ground / ressure mode | Time / ground / ressure mode |

| Lifting method | Linear slide electric lifting system | Linear slide electric lifting system | ||

| Size | 600x600x 1250 mm | 600x600x 1250 mm | 750x800x 2000 mm | 650x570x 1100 mm |

| Intelligent management | Amplitude/Quality/Data/Safety Management | Amplitude/Quality/Data/Safety Management | Amplitude/Quality/Data/Safety Management | Amplitude/Quality/Data/Safety Management |

| weight | 85 KG | 120 KG | 350 KG | 100 KG |

| Generator circuit | Digital intelligent auto frequency tracking / Circuit constant voltage | Digital intelligent automatic frequency tracking | Digital intelligent automatic frequency tracking | Digital intelligent automatic frequency tracking |

| Control system | BONNESONIC | BONNESONIC | BONNESONIC | BONNESONIC |

| Control mode | Button/External Control Mode | Button/External Control Mode | Button/External Control Mode | Button/External Control Mode |

| language | Chinese/ English | Chinese/ English | Chinese/ English | Chinese/ English |

| Safety management | password protection | password protection | password protection | password protection |

| Operation interface | 10 Inch external touch screen | 7 Inch external touch screen | 4.3Inch external touch screen | 4.3Inch external touch screen |

| Feature | USB data export/welding record/data statistics | USB data export/welding record/ data statistics | welding record/data statistics | welding record/data statistics |

Ultrasonic welding machine with touch screen

Packing for shipment

Packing for shipment

Why choose bonne?

We firmly believe that we have excellent ultrasonic welding solutions for every application.

In addition to accuracy, strength and minimum particle release, process verification and traceability are also important quality standards. Ultrasonic welding is considered the most suitable joining technique.

From the initial idea to actual application and development, to process optimization, bonne will go hand in hand with you to provide you with the best solution.