Basic Info.

Model NO.

DAF

Power

3.5~7.5kw

Logo

Customized

OEM

Acceptable

Material

Carbon Steel Stainless Steel

Use

Wastewater Treatment

Advantage

Plug and Play

Style

Air Floatation

Transport Package

Seaworthy Packaging

Specification

carbon steel Q235

Trademark

Meta

Origin

China

Production Capacity

200 Set Per Year

Product Description

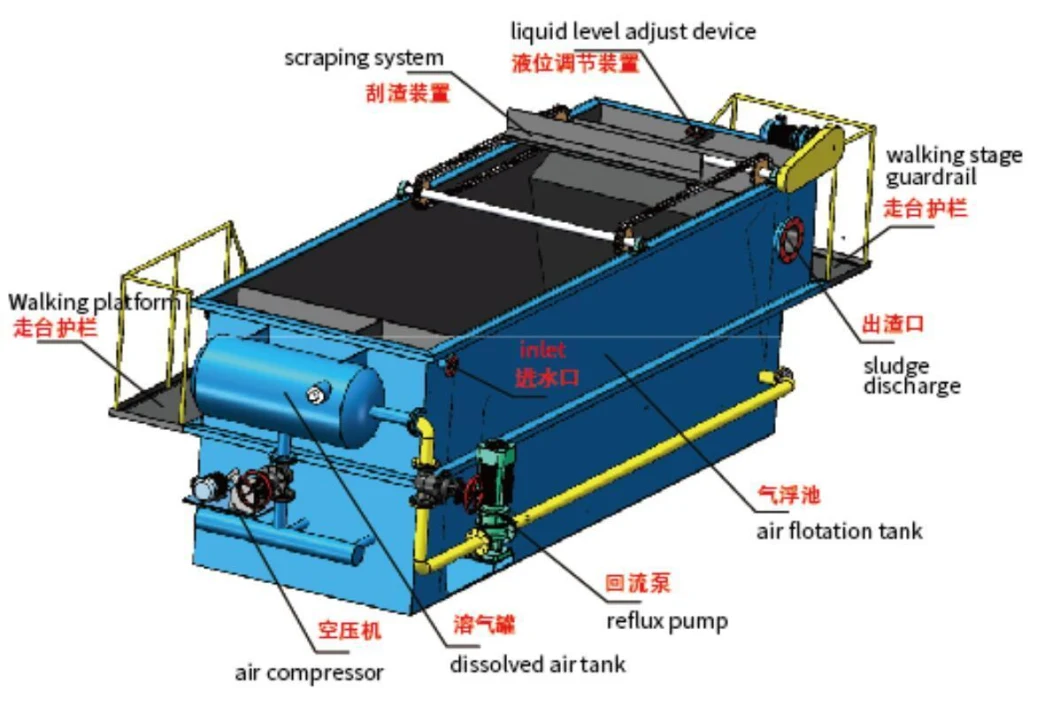

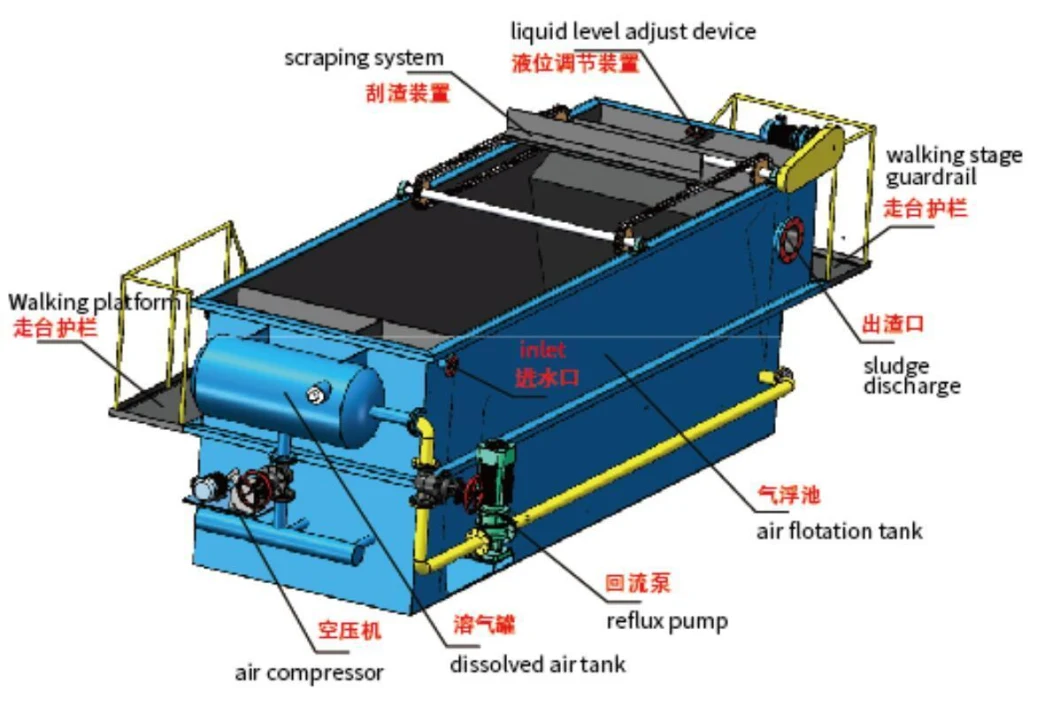

Dissolved Air Flotation equipment

One step solution from design, produce, installation, commissioning.

The DAF Separator provides effective of suspended solids, fats, oils and greases from liquids by dissolved air flotation. Flotation of the solids is accomplished by the introduction of microscopic air bubbles into the process water. As the bubbles rise, they attach themselves to the particles in suspension and carry them to the surface for removed.

Dissolved Air Flotation Used in Corresponding water quality as follow :

high SS, and the specific gravity of suspended solids or contaminants is generally slight greater than water, like: oil and Fats, Food Industry effluents with high solids concentration, Sludge Thickening, Galvanizing Electro, Pharmaceutical , Leather Industry, etc.

Dissolved Air Flotation Features

1. Design treatment capacity:4-300 m3/h.

2. High-rate clarifier for high SS water (light particles, oil and colloid).

3. Fully (100%) manufactured in the factory, and no need secondary welding. It costs 3h for 2 manpower to assemble.

4. Indoor or outdoor layout (environmental temperature should be over 0°C).

5. Apply to automatic & continuous operation.

6. Design life: Carbon steel material: >10years;

304 Stainless steel material: >20years.

316 Stainless steel material: >25 years.

Dissolved Air Flotation Advantages

1. Extremely high scrapping speed (2-3 times faster than conventional design) and safety operation because of using fully reverse and closed scraper.

2. High hydraulic load and low footprint because of horizontal plates in the separation zone, more effective separation and optimization hydraulic flow in the separation area.

3. Better outlet water quality because of W-shape sludge sedimentation hopper.

4. Effectively minimize chemical consumption because of re-flocculation performance of reverse scraping design.

5. No blind angle in scum collection chamber.

Our Services

Our Services

1. Detailed installation manual and maintenance guideline are provided with the equipment.

2. Technical training and site commissioning and installation are available for you.

3. Any equipment is sue, we will stand by. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

One step solution from design, produce, installation, commissioning.

The DAF Separator provides effective of suspended solids, fats, oils and greases from liquids by dissolved air flotation. Flotation of the solids is accomplished by the introduction of microscopic air bubbles into the process water. As the bubbles rise, they attach themselves to the particles in suspension and carry them to the surface for removed.

Dissolved Air Flotation Used in Corresponding water quality as follow :

high SS, and the specific gravity of suspended solids or contaminants is generally slight greater than water, like: oil and Fats, Food Industry effluents with high solids concentration, Sludge Thickening, Galvanizing Electro, Pharmaceutical , Leather Industry, etc.

Dissolved Air Flotation Features

1. Design treatment capacity:4-300 m3/h.

2. High-rate clarifier for high SS water (light particles, oil and colloid).

3. Fully (100%) manufactured in the factory, and no need secondary welding. It costs 3h for 2 manpower to assemble.

4. Indoor or outdoor layout (environmental temperature should be over 0°C).

5. Apply to automatic & continuous operation.

6. Design life: Carbon steel material: >10years;

304 Stainless steel material: >20years.

316 Stainless steel material: >25 years.

Dissolved Air Flotation Advantages

1. Extremely high scrapping speed (2-3 times faster than conventional design) and safety operation because of using fully reverse and closed scraper.

2. High hydraulic load and low footprint because of horizontal plates in the separation zone, more effective separation and optimization hydraulic flow in the separation area.

3. Better outlet water quality because of W-shape sludge sedimentation hopper.

4. Effectively minimize chemical consumption because of re-flocculation performance of reverse scraping design.

5. No blind angle in scum collection chamber.

| Model | Capacity (t/h) | Dissolved gas water (t/h) | Main dynamo power (kw) | Air compressor power (kw) | Dissolved tank size (mm) | Overall dimension (mm) |

| YW-5 | 4-5 | 1.5-2 | 3 | 1.5 | 400*1000 | 3300*1800*2200 |

| YW-10 | 8-10 | 2-3 | 4 | 1.5 | 500*1512 | 4000*2100*2200 |

| YW-20 | 15-20 | 5-7 | 7.5 | 1.5 | 500*1512 | 4600*2400*2200 |

| YW-40 | 30-40 | 8-13 | 7.5 | 1.5 | 600*1880 | 6000*2600*2400 |

| YW-50 | 40*50 | 15*20 | 7.5 | 2.2 | 600*1880 | 7000*2600*2400 |

| YW-70 | 60-70 | 22-30 | 11 | 2.2 | 650*2034 | 8400*2800*2400 |

| YW-80 | 70-80 | 24-32 | 11 | 2.2 | 650*2034 | 9200*2800*2400 |

| YW-105 | 90-105 | 30-35 | 15 | 3 | 700*1980 | 10000*2800*2600 |

| YW-150 | 125-150 | 60-80 | 22 | 4 | 700*1980 | 13500*2800*2600 |

| YW-200 | 175-200 | 80-100 | 30 | 5.5 | 800*2100 | 15800*2800*2600 |

| YW-250 | 225-250 | 100-120 | 37 | 5.5 | 800*2400 | 15200*3400*2600 |

| YW-300 | 280*300 | 120*180 | 37 | 5.5 | 1000*2900 | 19200*3400*2800 |

Our Services

Our Services 1. Detailed installation manual and maintenance guideline are provided with the equipment.

2. Technical training and site commissioning and installation are available for you.

3. Any equipment is sue, we will stand by. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.